An Illustrated History of Old Sutton in St Helens, Lancashire

Part 23 (of 95 parts) - History of Industry in Sutton Part 4 - Crone & Taylor

Researched & Written by Stephen Wainwright ©MMXX Contact Me Research Sources

Researched & Written by Stephen Wainwright ©MMXX

Old Sutton in St Helens

Crone & Taylor

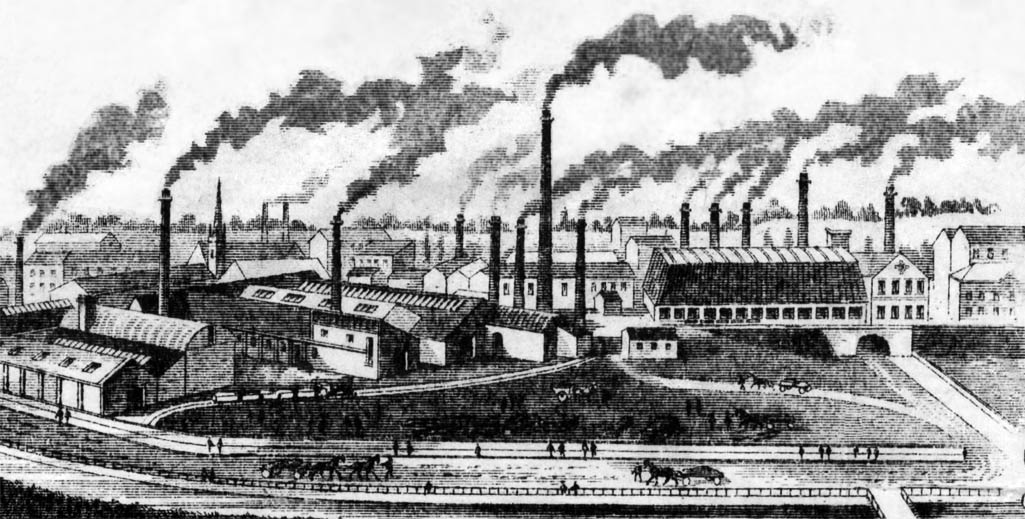

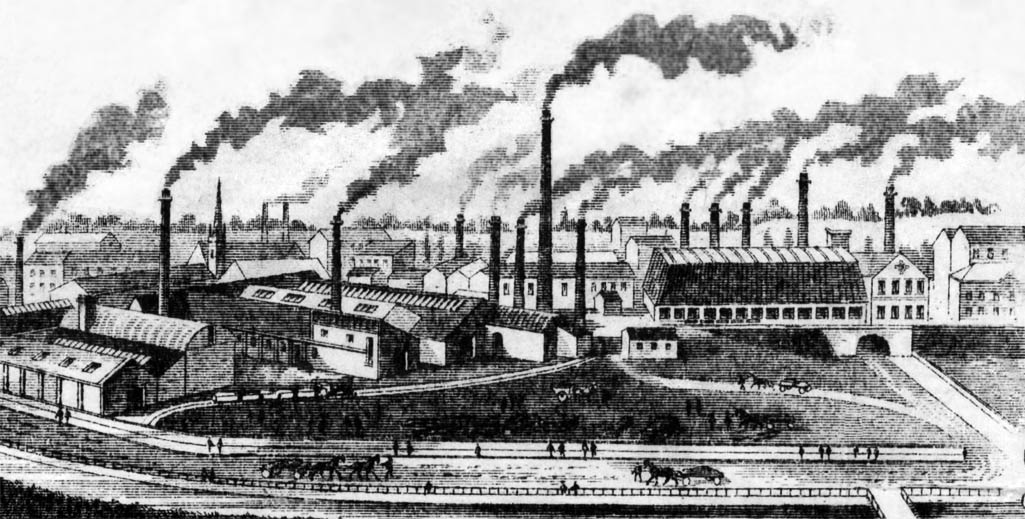

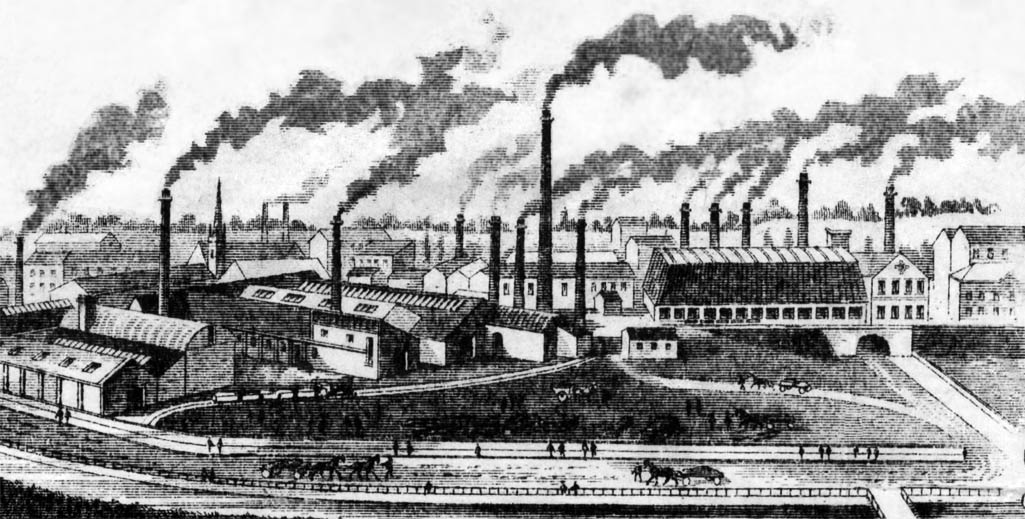

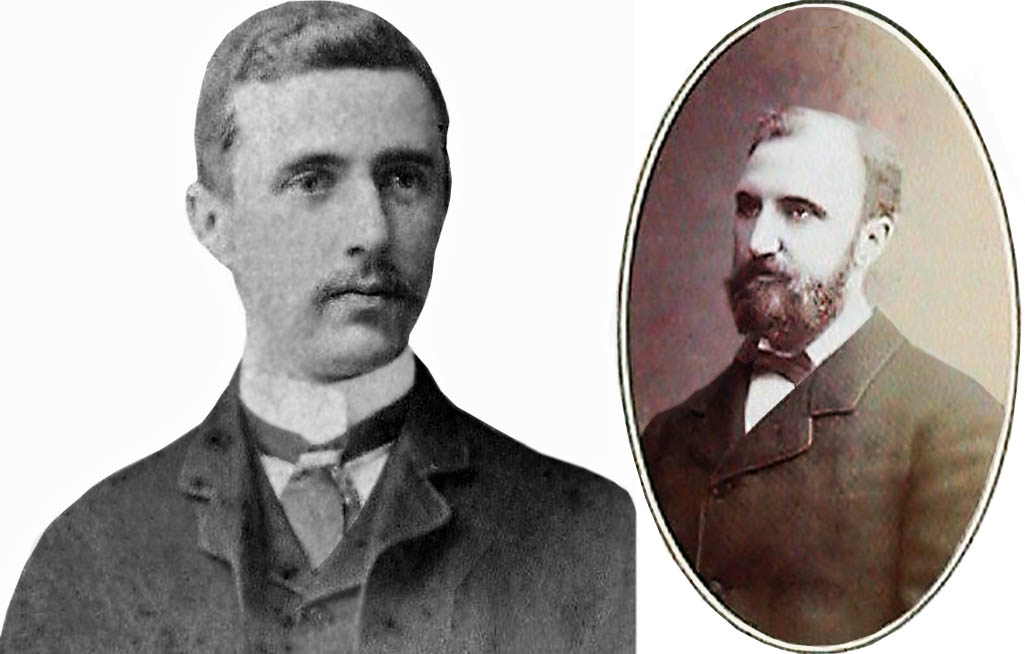

An illustration of the Sutton Oak works of Crone & Taylor in Worsley Brow, manufacturers of artificial manure

An illustration of the Sutton Oak works of Crone & Taylor

An illustration of Crone & Taylor

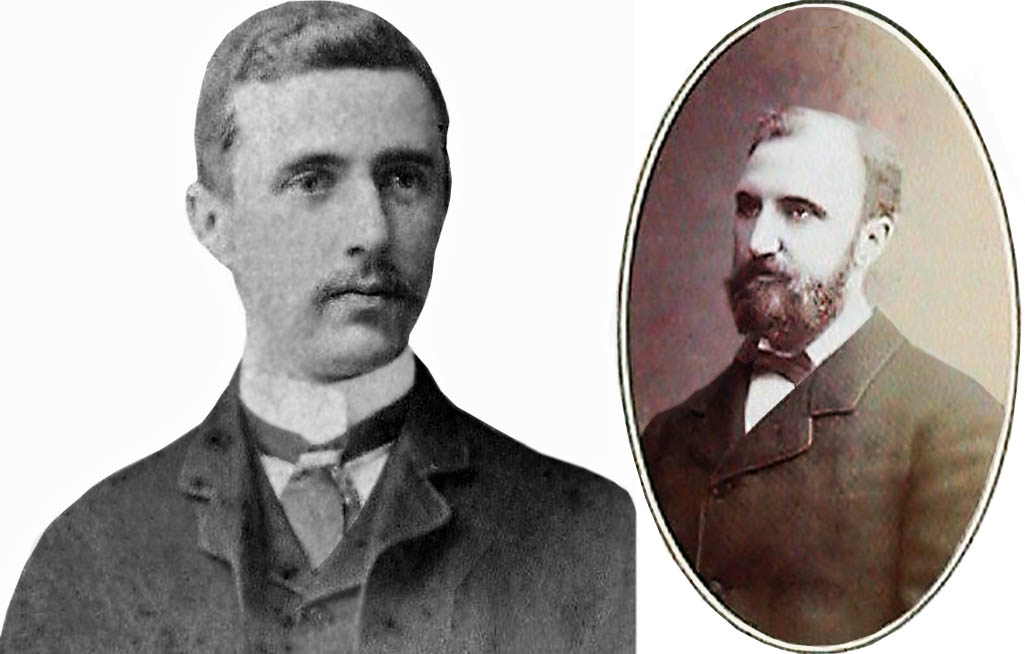

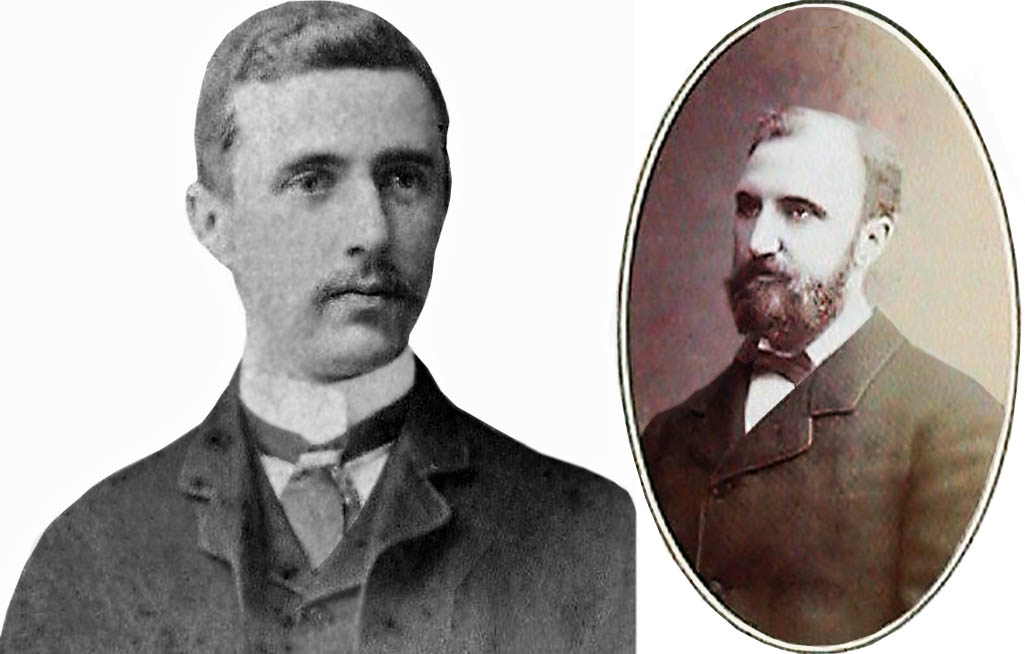

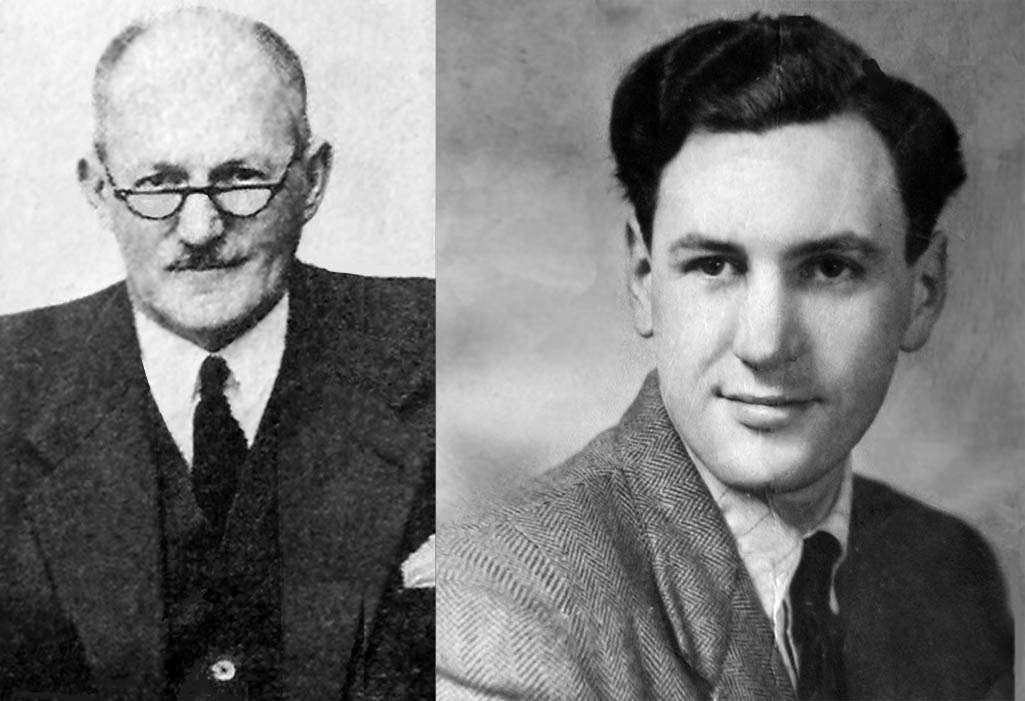

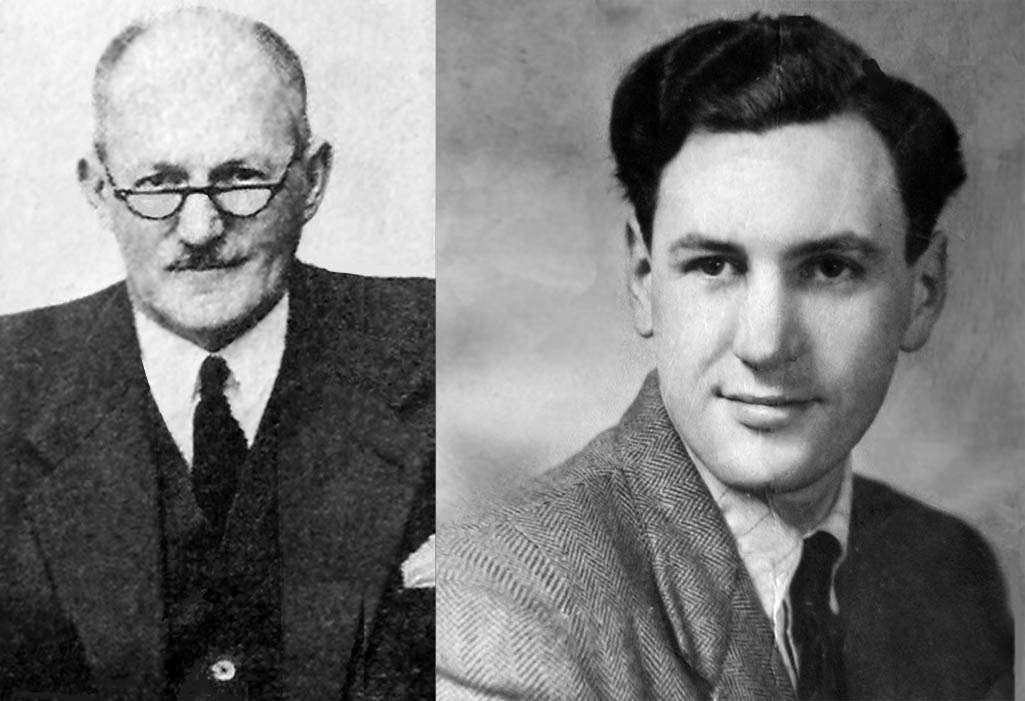

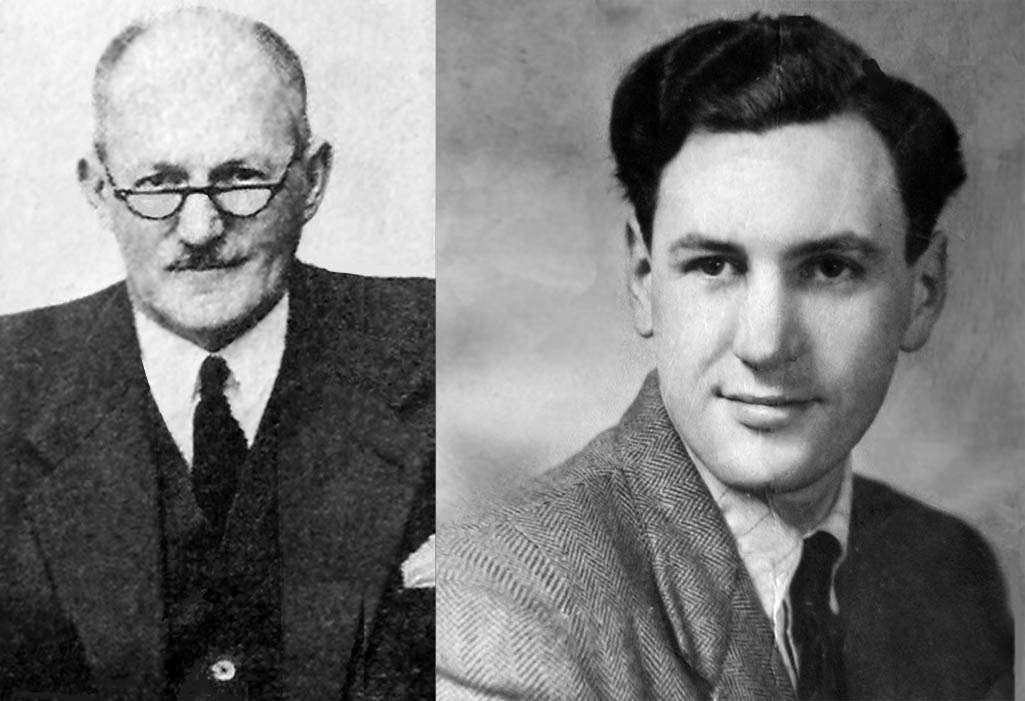

The founders of Crone & Taylor of Sutton Oak, David Cronk Taylor (left) and John Crone (right) - contributed by Sheila Crone

Crone & Taylor’s founders David Cronk Taylor (left) and John Crone

David Cronk Taylor (left) and John Crone

George Downs of Mill Brow in Sutton was a traveller for Crone & Taylor, visiting farms on behalf of the company. In April 1893 it was reported that he had inherited £50,000 from his uncle George Sugden, a founder of a Bradford cloth manufacturer. In today’s money £50,000 is worth about £6 million.

For some years Crone & Taylor's storeroom served as the chapel for the undenominational Welsh. This was prior to 1893 when they acquired the Methodist Church's chapel in Lancots Lane. To gain access to the storeroom the congregation had to pass through a hole in the surrounding wall and the chapel became locally known as "The Hole in the Wall church".

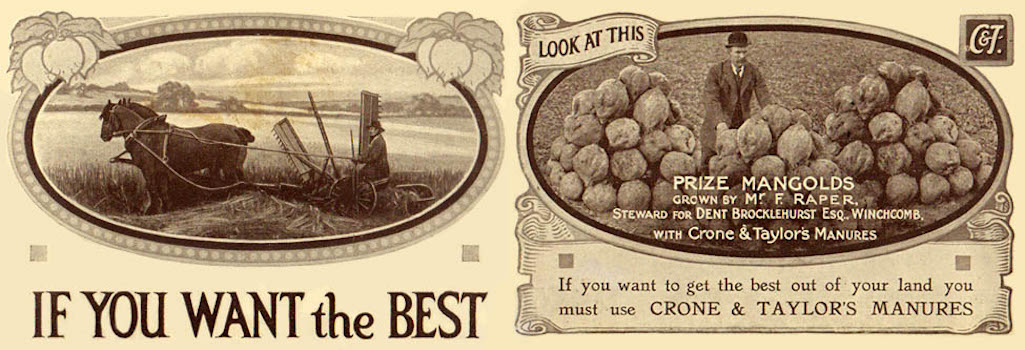

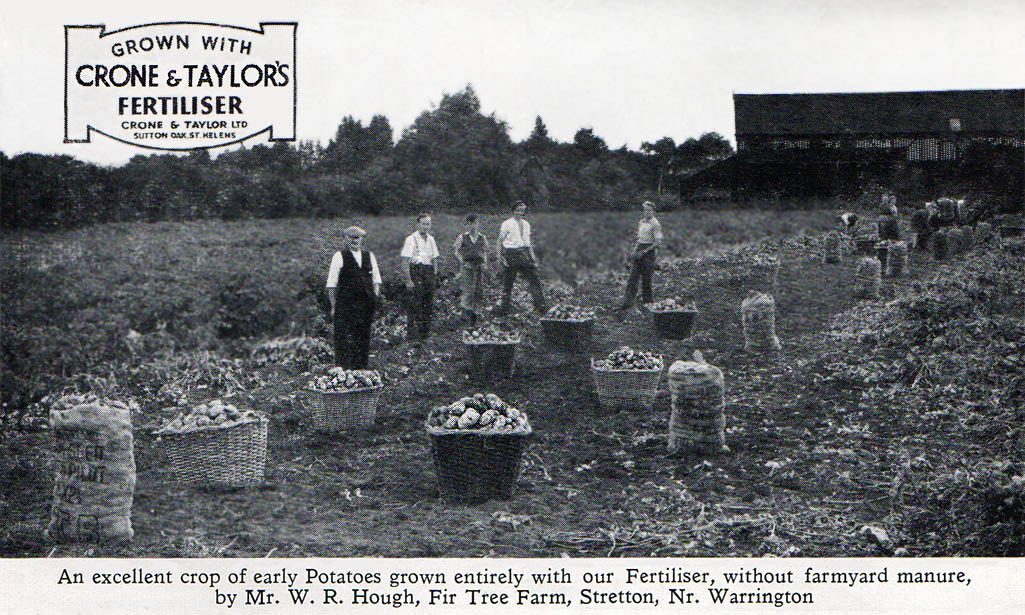

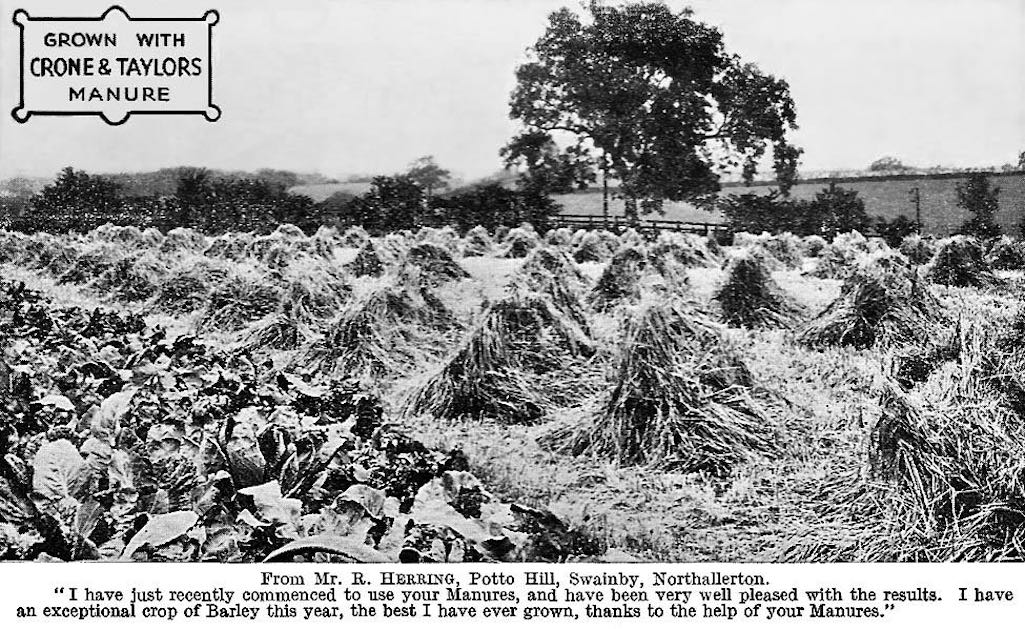

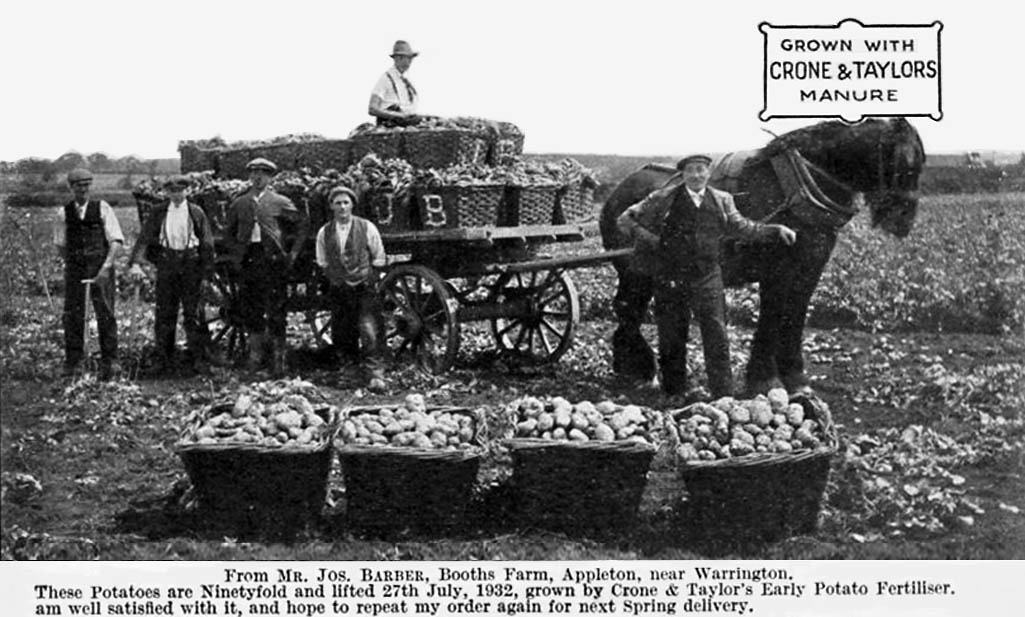

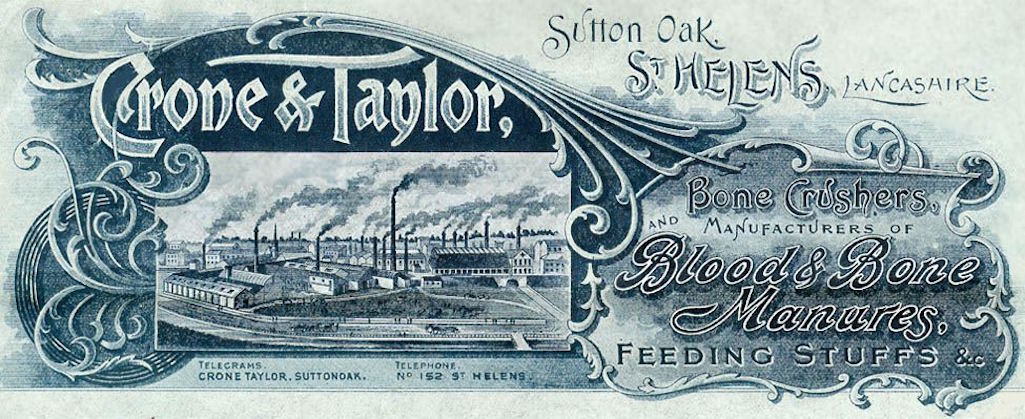

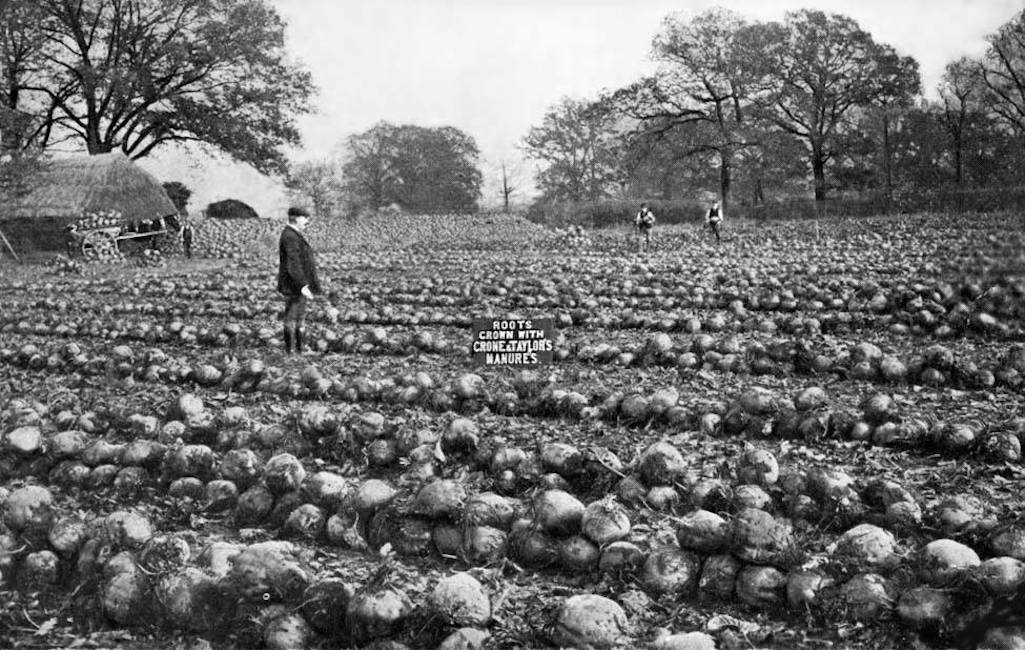

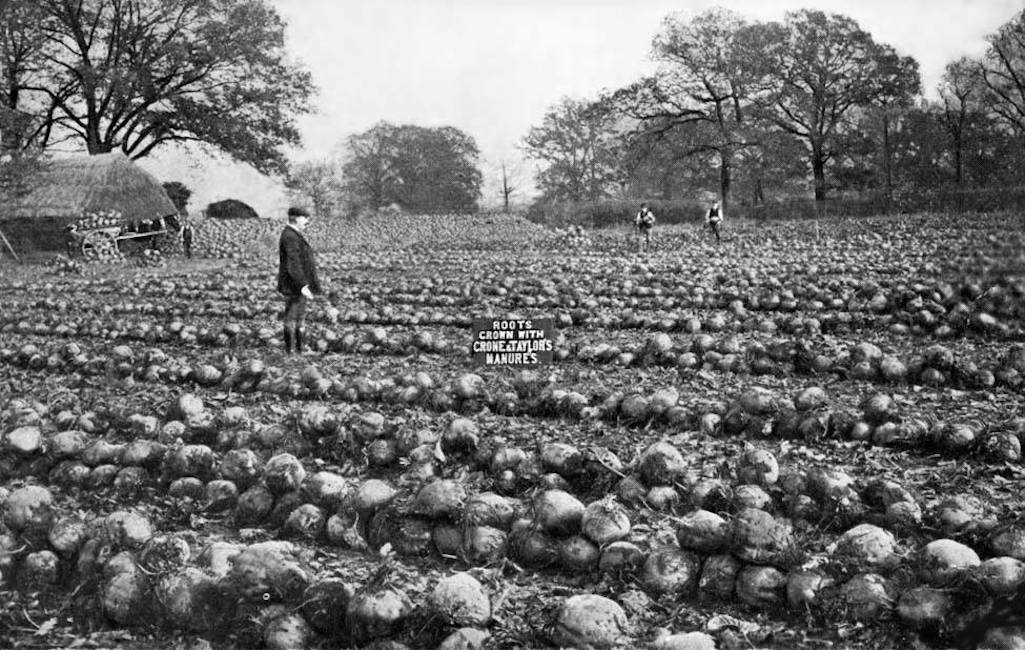

Crone & Taylor promotional picture postcard extolling the benefits of their manure for growing root vegetables

Crone & Taylor promotional postcard extolling the benefits of their manure

Crone & Taylor promotional postcard

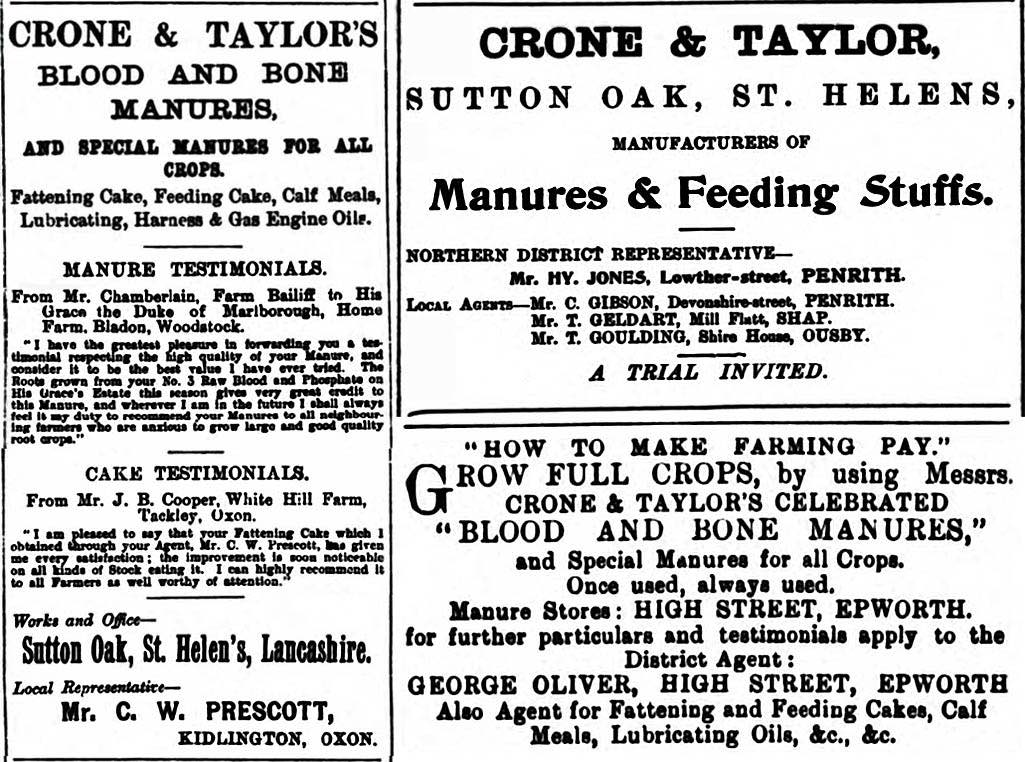

Personal contact with their customers was considered very important and the company appointed agents in a number of districts to liaise with farmers and take orders. They looked for individuals that already had business connections with the agricultural community and who regularly attended markets. After all it would be many years before farmers had telephones and so face-to-face contact with their customers was vital. Travellers representing Crone & Taylor would look for new business in areas were agents had yet to be established.

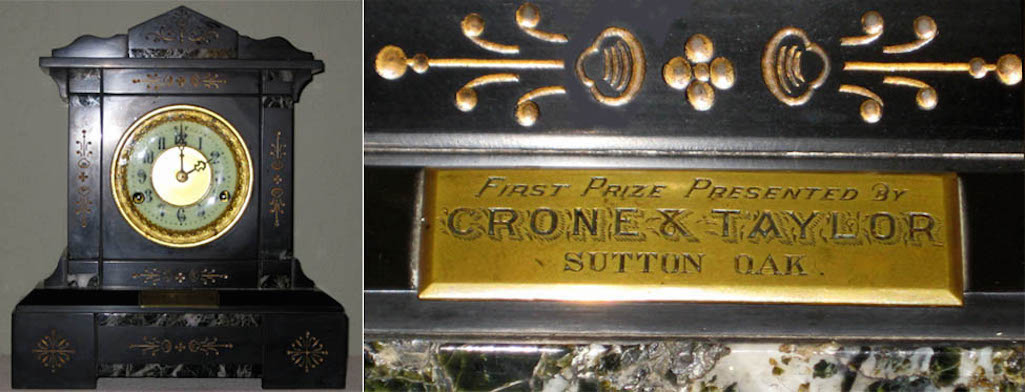

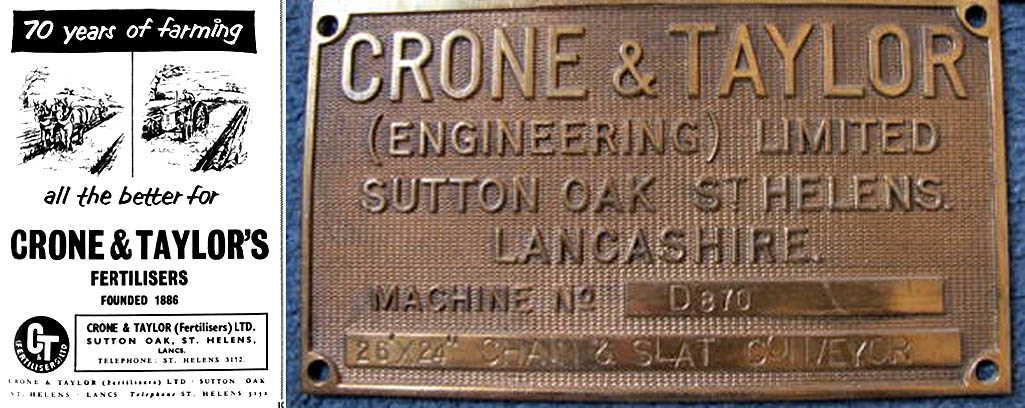

Crone & Taylor's three regional strongholds outside of Lancashire were Cumberland, Lincolnshire and Wales, although they also had a good presence in Oxfordshire and Buckinghamshire. Annual dinners and competitions were held to encourage loyalty to their products.

On December 17th 1897 the Monmouthshire Beacon reported that the company had held their annual dinner at the King's Head Hotel in Monmouth for almost thirty farmers from the district. David Taylor was in the chair, with the company's local agent as vice-chair. Mr Taylor said he was "coming to consider this annual fixture as a meeting of old friends". Prizes were handed out for the best fields of swedes and mangolds.

Judges were appointed to inspect crops and award prizes in various districts. These were reported at length in local newspapers, giving the company much free publicity. At the Crone & Taylor Green Crop Awards in Penrith in October 1903, the Cumberland & Westmorland Herald stated that the judges' report had praised the Sutton Oak firm's product. They said: "the manure supplied by you is gaining a wonderful power in the district, and the result can be easily detected".

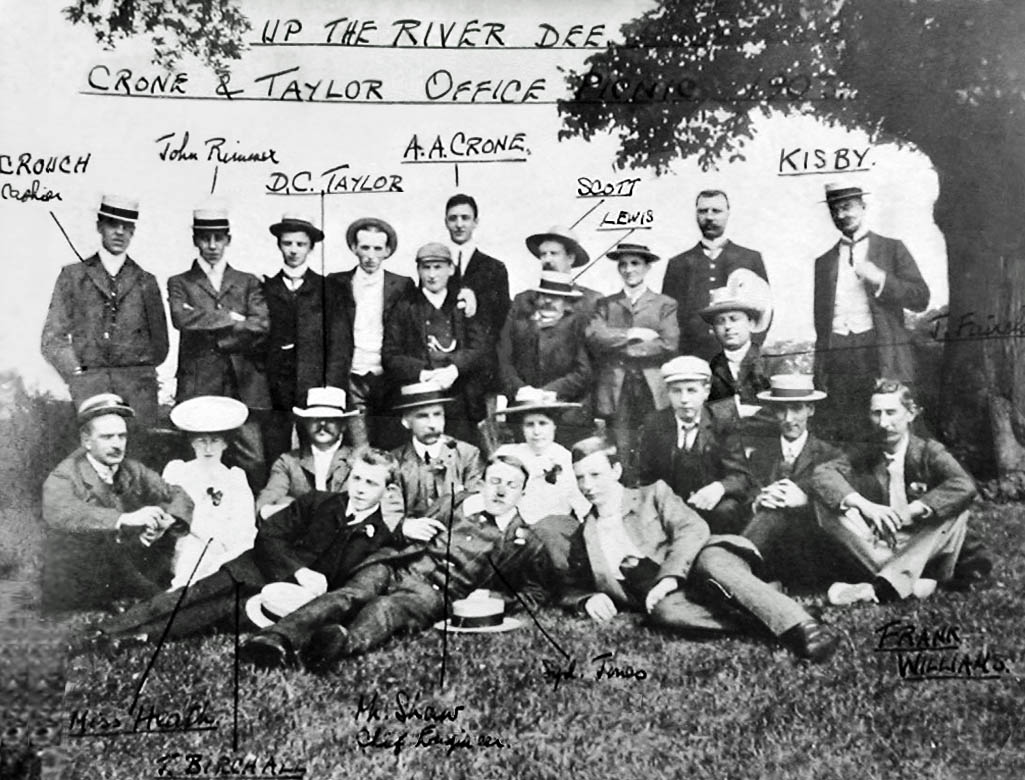

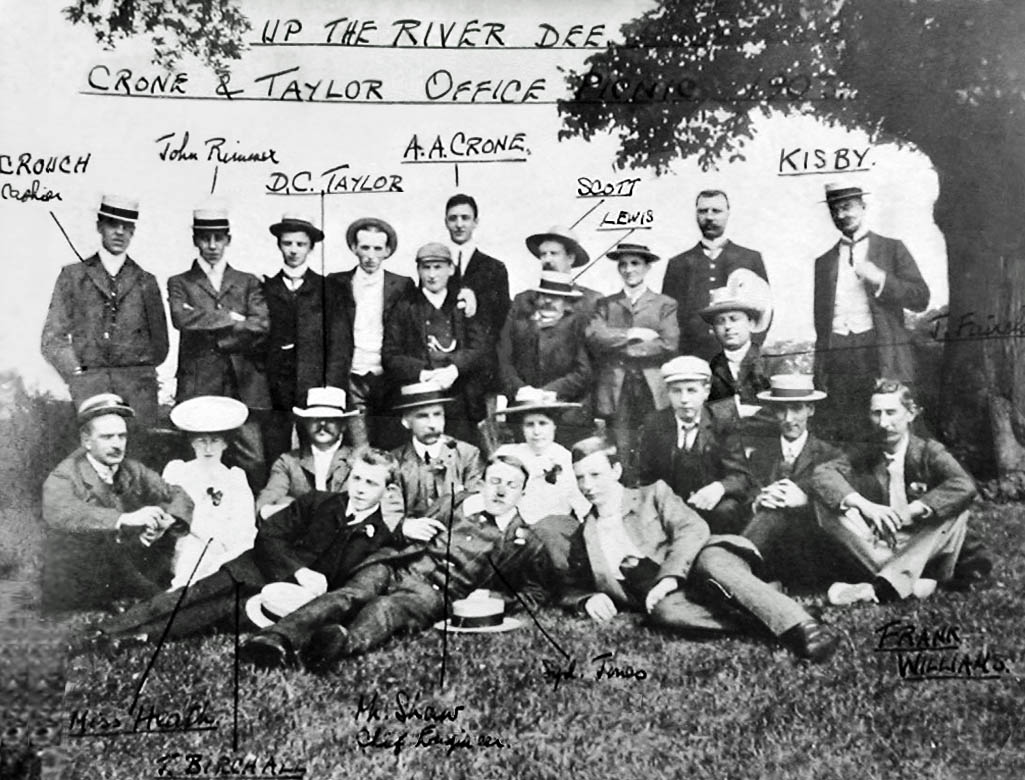

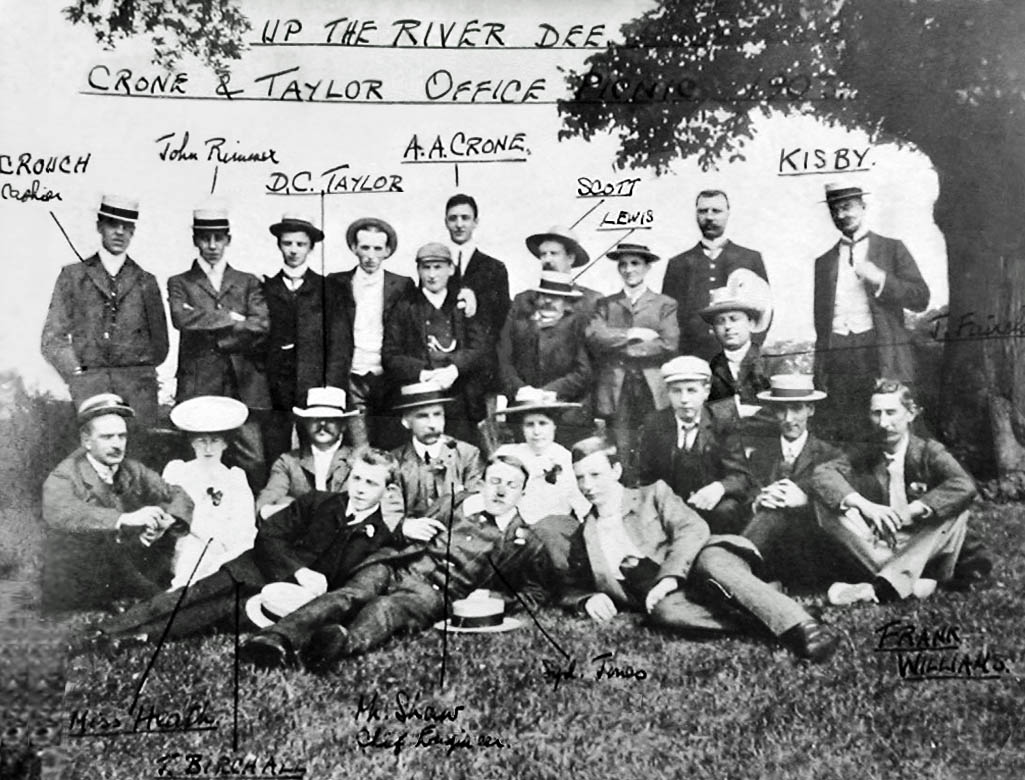

Crone & Taylor office outing to the River Dee in 1903 - contributed by Sheila Crone

Crone & Taylor office outing to the River Dee in 1903

Outing to the River Dee in 1903

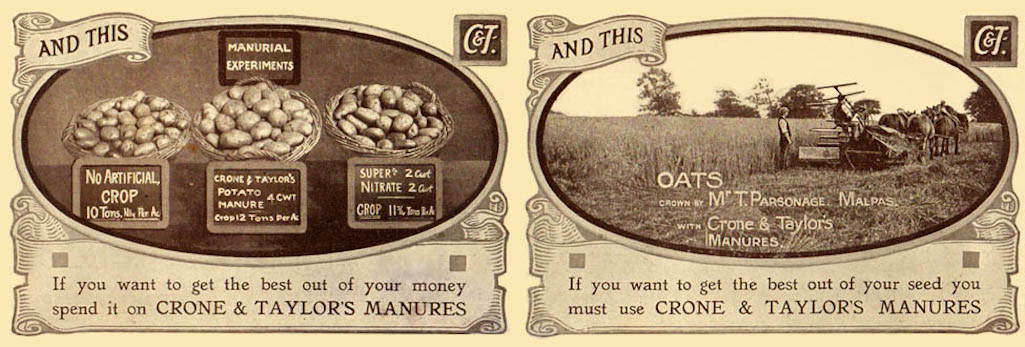

In 1925 the two founders of the business became linked by marriage when John Crone's son Arthur (known as Alan) Crone married David's daughter Mary Beatrice. During the '30s the company advertised their main product as "balanced fertiliser" with the slogan "Keep the bank balance right by using balanced fertilisers made by Crone & Taylor, Ltd."

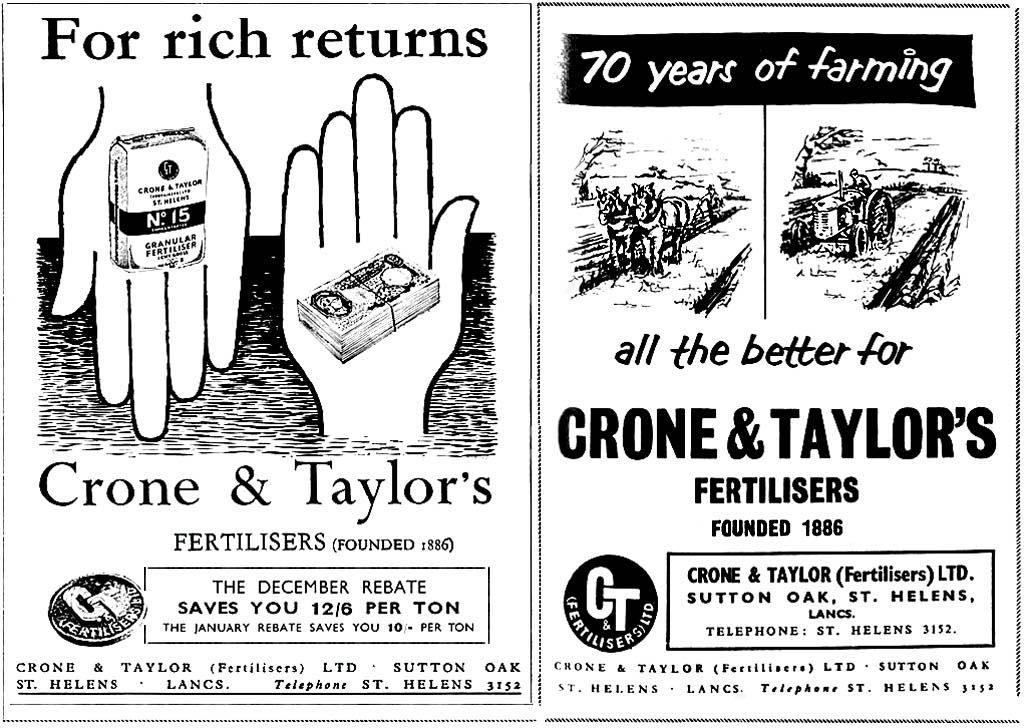

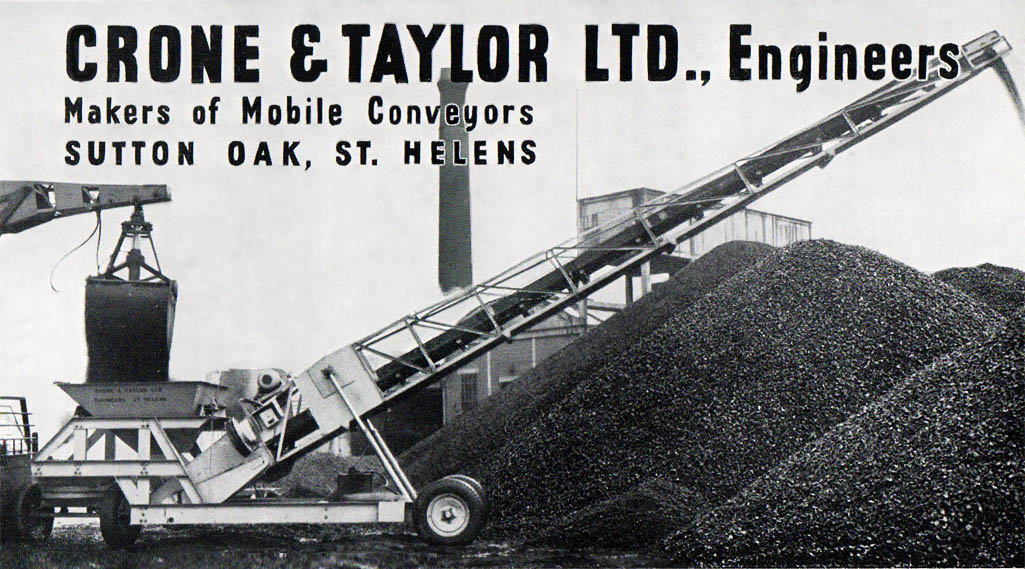

The latter's machine shop was at the bridge end of Ellamsbridge Road and was elevated about two metres above the ground as a result of periodic flooding from Sutton Brook. The company was so successful with their engineering products that they began phasing out the fertiliser side of their business. They even published their own news sheet, which they called 'Conveying Times'.

L - R: Arthur Alan Crone and David Cronk Taylor (taken on his 100th birthday) - contributed by Sheila Crone

Arthur Alan Crone and David Cronk Taylor (taken on his 100th birthday)

Alan Crone and David Taylor

L - R: Managing Director Geoffrey Taylor and Technical Director Antony Crone - contributed by Sheila Crone

Managing Director Geoffrey Taylor and Technical Director Antony Crone

Geoffrey Taylor and Antony Crone

The article described how C & T had spent between £40,000 to £50,000 over the last few years improving its efficiency. The company’s managing director was now Stan Walker, who had succeeded Geoffrey Taylor. He regularly left his “luxurious office” to promote his firm, spending about 40,000 miles on the road each year.

Mr. Walker described to the newspaper how the streamlining of the coal industry during the ‘60s had forced C & T to diversify their interests yet again. The Reporter said they had begun specialising in package deals and with a "smart team backing him, Mr Walker contacts buyers, advises them on their needs, produces the scheme and even helps with finance. They have also entered the building trade, and are at the moment hard at work constructing process plants for the production of cement bricks, currently popular. Their crying need is for turners, platers, welders and fitters." Mr Walker also explained to the Reporter how his company hoped to double the size of their existing premises, which then stood on three acres of land.

In another article in the St Helens Reporter published on October 3rd 1969 Stan Walker said their firm considered themselves to be “engineers in mechanisation”. Recently they had been the main contractors in the design and build of a £130,000 coal concentration depot at Norwich and since the Beeching Report of 1961 had recommended the concentration of coal sidings, Crone & Taylor had built 48. Mr Walker said the company’s current order book included the building of a large coal concentration depot at Aberdeen, the first to be built in Scotland.

The Reporter on January 16th 1970 described how a 96-ft. high gantry-like structure that towered over Crone and Taylor's engineering yards was causing much comment. With Apollo 11 still very much in people's minds, remarks were being made that it resembled a rocket gantry. It was in fact a £30,000 ship loader, which would be dismantled before being sent to Greece where the machine would be used in grain exports. It was one of several similar loaders that the firm had sent abroad during the past twelve months, with two having been despatched to the West Indies.

In 1971 Crone & Taylor was acquired by Wm. Brandt & Sons and the plant closed in 1983. A large quantity of documents and photographs was donated by Crone & Taylor to the St Helens Local History & Archives Library during the 1970s and details can be viewed in their online catalogue. Below is a further collection of advertisements and promotional items pertaining to the company.